#WalkerS2 – The World's First #HumanoidRobot Capable of Autonomous Battery Swapping.

— UBTECH Robotics (@UBTECHRobotics) July 17, 2025

→ Anthropomorphic Bipedal Locomotion → Autonomous hot-swappable battery system→ Autonomous battery swapping, 24/7 continuous operations

Swarm Intelligence 2.0 is coming soon! pic.twitter.com/gDyLWrgG25

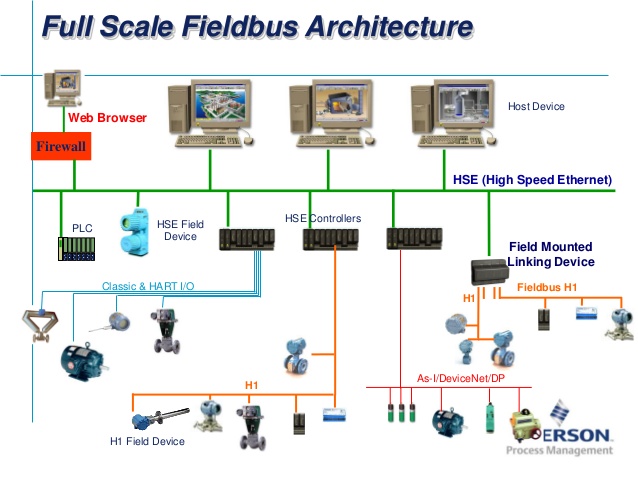

For decades, industrial automation has been shackled by Fieldbus systems controlled by Western corporations: complex, cable-heavy networks governed by proprietary protocols, rigid architectures, and costly vendor lock-in.

By deploying ultra-dense 5G Advanced (5G-A) networks nationwide, China isn’t just upgrading connectivity. It’s turning wireless itself into the central nervous system of smart factories. Here’s why this changes everything:

⚡ 1. Connectivity Is the Control Layer

5G-A’s ultra-reliable low-latency communication (uRLLC) now delivers sub-1ms latency and 99.9999% reliability, matching or exceeding wired fieldbus performance. Real-time control no longer lives in closed-loop cables made by Siemens; it rides the airwaves.

🤖 2. Plug-and-Play Industrial Devices

Robots, AGVs, and humanoids join the network like smartphones on cellular:

No rewiring: Machines roam freely, unbound by Ethernet cables.

Zero protocol translation: Native IP communication erases CANopen/Profinet/Modbus gateways.

Instant onboarding: Authenticate via SIM/eSIM, and the network dynamically allocates resources.

🪫 No More Royalty Traps: Open 3GPP standards replace proprietary protocol stacks.

🔓 Vendor Lock-in Crumbles: Mix and match robots, sensors, and PLCs without compatibility purgatory.

📈 Infinite Scalability: Spin up 1,000 AGVs without recabling a single production line.

Why China? Scale + Speed + Sovereignty

🌐 Dense Deployment: Factories in Shenzhen, Shanghai, and beyond already operate in contiguous 5G-A coverage zones. ⏱️ First-Mover Aggression: State-backed rollout prioritizes industrial 5G over consumer use cases. 🔋 Ecosystem Leverage: Huawei, ZTE, and local robotics giants (like Siasun) co-design hardware/network layers.